On May 9, in view of the inconsistency between the manual off-line and automatic line coil packaging codes, the MCC Baosteel zhangang Co., Ltd. set up a research team to independently develop and realize the effective integration of automatic line packaging and traditional manual packaging, so as to realize the full-automatic packaging of the original manually packed steel coils, and explore the direction for the development of unmanned production of packaging business. The research group of zhangang iron and Steel Co., Ltd. of MCC Baosteel actively contacted the equipment side of the automatic line to optimize the packaging system through continuous exploration of solutions and optimization schemes, and made full use of the fully automatic functions of the wrapping machine and the circumferential and radial balers, and added code modification function in the main operation screen to realize the effective integration of automatic line packaging and traditional manual packaging.

For a long time, the traditional mode of coil packaging is mainly manual off-line packaging or semi-automatic line operation. In order to solve this problem, the company organized technical personnel and the first-line packaging operator to the site investigation. After more than one month’s investigation and test, the C-hook position of the automatic line was optimized, and the C-hook brake insurance and safety anti-collision safety device were made to realize the online paper wrapping operation. During this period, in order to ensure the effectiveness of the test operation process and data, relevant technical and management personnel such as security team, equipment side, Ma Anshan Steel Packaging, unit operator of Zhanjiang iron and steel cold rolling plant were invited to collect and verify the test data. CHAMC Baosteel zhangang Co., Ltd. actively seeks for reform and changes in response to the situation. It has set up a research group to actively explore intelligent and unmanned production. Taking the improvement of production efficiency as the main line, it has taken the initiative to change the production organization mode and innovate the production operation methods. It has put forward the paper wrapping operation scheme for the automatic line on the off-line coil packaging, optimizes the off-line packaging operation mode, reduces the labor cost and improves the field efficiency Rate. Creativity changes the world. All employees of the company always carry forward the enterprise of “no delay, no slack” all the time, bravely climb the peak, actively explore the intelligent and unmanned production of front-line jobs, accelerate the pace of enterprise transformation, and open up the packaging brand of MCC.

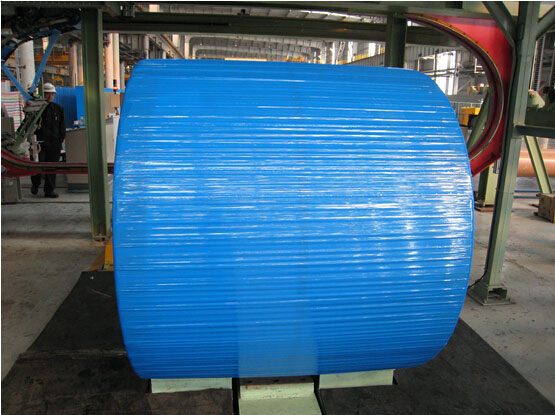

MCC Baosteel zhangang Co., Ltd. helps Zhanjiang steel to export its super large steel coils to Italy. On May 4, MCC Baosteel zhangang completed the production of well shaped frame for Zhanjiang iron and steel super large coil, ensuring the smooth export of steel coil with outer diameter of 1793 mm and single weight of 23.53 tons to Italy. In order to ensure the safety of the roll in the logistics link, the company has made a customized scheme for the project: increase the number of bottom wood to improve its bearing capacity; increase the volume by 23% to improve its bending strength; shorten both ends of the bottom timber by 100 mm to improve the stress strength of the upper and lower wood fulcrum. In order to confirm the reliability of the well frame, the company also carried out field verification such as simulated coil test installation, secondary installation after removal, loading test run, etc., and the conclusion that there is no displacement of the upper wood, no crack under heavy pressure and no deformation at the supporting point of the upper and lower wood passes smoothly. The relevant person in charge of Baosteel zhangang Co., Ltd. of MCC said that the successful operation of the well frame has far-reaching significance in sharing cost improvement achievements with owners under the settlement mode of ton steel. The company will always adhere to the “bold innovation, strive for the first-class” product production concept, the pursuit of the ultimate, so that Zhanjiang iron and steel assured satisfaction.

MCC Baosteel zhangang Co., Ltd. has realized automatic coil packaging and transformed into unmanned production Related Video:

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Packing Factory In Dandenong , Hunan Victory Paper & Plastic Packing Co. Ltd , Packing Manufacturers In Gujarat , We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.